If you are planning to spend several £1000’s to fit new fascia’s and soffits on your house, you want them to look good, which is why POLYTOPS nails and pins are an ideal choice for fastening them to your building.

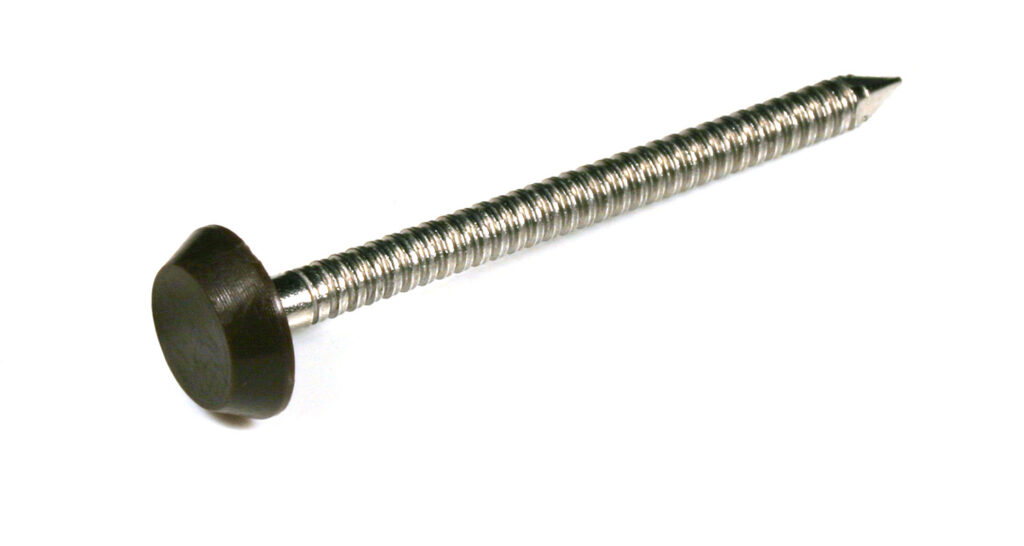

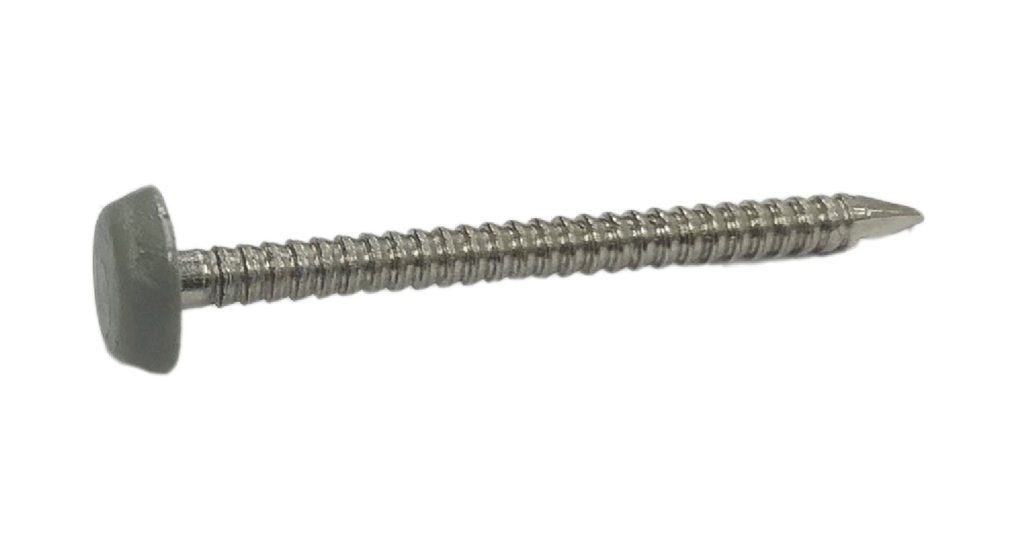

POLYTOPS are a polymer headed fastener which is made of A4 marine grade stainless steel with a colour plastic moulded head. The colour top will match and blend in with the colour of the new fascia and soffit uPVC / PVCu boards being fitted. .

POLYTOPS are made in conjunction with the PVCu board manufacturers to closely match their boards colour ranges.

POLYTOPS nails are used to fit the fascia board, these being 40mm, 50mm and 65mm, and are strong enough to take the heavyweight bearing. POLYTOPS pins are 25mm, 30mm and 40mm and are used to fasten lighter soffit boards.

So Why POLYTOPS?

All POLYTOPS are made with an extra toughen plastic material so they can really take the hammering that can be required to drive them into the boards without scratching, cracking or breaking, ensuring they look good when in place.

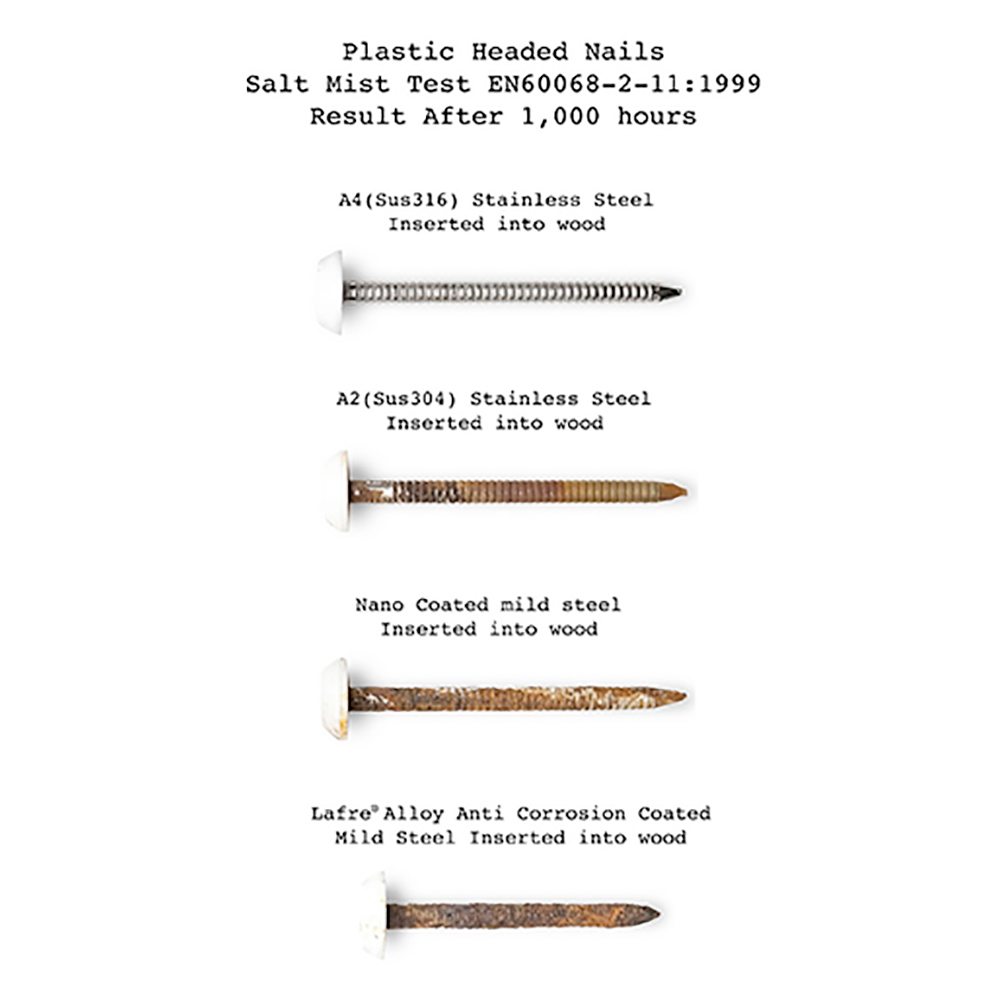

Most importantly Polytops are made with A4 (SUS316) marine grade stainless steel (typically referred to as A4). This is very important as A4 does not corrode and rust when it comes into contact with salt in the atmosphere. If a fastener has been used and it is not manufactured from A4 stainless steel, then there is a risk of rusting and leaking brown rust stains down the front of your newly fitted fascia and soffit boards.

A4 are made with a heavier mix of Nickel and Molybdenum, which helps to protect the iron within the carbon steel (that is stainless steel) from corroding. Lesser materials like A2 stainless steel and zinc plate stainless steel do not contain this protective mix and are therefore much more vulnerable to corrosion.

A Very Simple Magnet Test

A4 marine grade stainless steel is not magnetic where as A2 stainless steel and zinc plated steel fixings are! This is due to how they are made, regarding the percentage of metal containing carbon steel – the element that will corrode, and this is magnetic.

So the more magnetic a fastener is, the higher the likelihood of it corroding. A4 is not magnetic which is why it doesn’t corrode.

I Don’t Live Near The Sea So This Isn’t An Issue?

It is correct to say that the closer a building is to the sea the greater the exposure to a saltwater atmosphere a fastener can have. However, there are several factors to take on board. Subject to wind direction, air from the sea can travel 50 to 70 miles inland. Also in winter, a heavily gritted surface like a main road, produces a high percentage of salt into the air and can corrode and damage metal which is near. Lastly, urban pollution containing chemicals can also have an effect and cause corrosion, resulting in rust staining. There is an element of rust-staining risk – even if your building is inland.