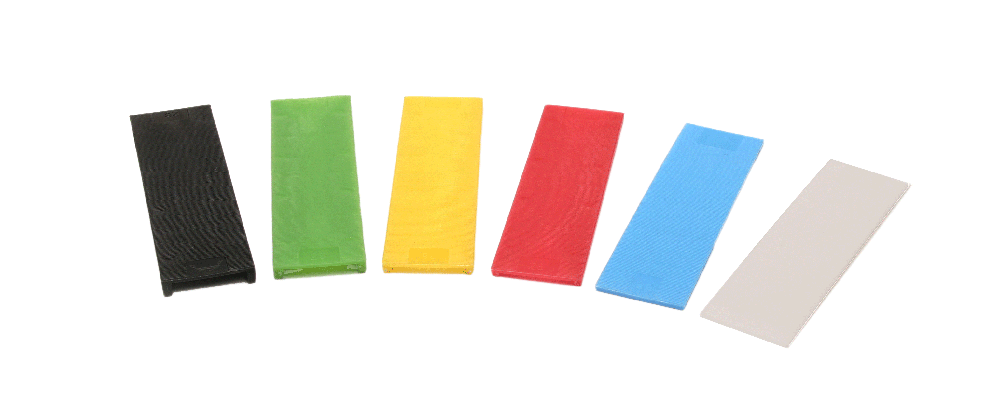

- Supports window blocks to distribute the weight of the glazed unit into the base frame profile

- Ensure the glazed unit is aligned and square to the frame

- Protects the edge structure of the glass

- Prevents contact between the glass and frame

- Stops the glass unit from slipping

- Increase security around fixing points to prevent the deflection of the frame extrusion

Why Are Packers So Important?

The majority of windows fitted in the UK are sealed double glazed units (approximately 93% of UK houses have double glazed units). The double glazed units are typically two planes of 4mm glass separated by a spacer bar and hermetically sealed all around the frame edge. These tubes vary in width from 6mm to 20mm+. For example, you can typically have a 4-20-4 which gives a 28mm unit.

What Is A Failed Unit?

If condensation is forming between the glass panes then that is a signal that the frame seal has failed and is allowing in moister. It is so important to use packers correctly during installation to help avoid premature failure in the frames. If the wrong material like wedges of timber, folded up cardboard and foam are used they can and will disintegrate over the years and not correctly support the frame. Even worse if no packing is used at all which means the double glazed unit is likely to be sitting in the water which can gathers at the bottom the frames and therefore will attack the unit’s seals. Purpose made plastic glazing and bridging packers are purposely designed to give the unit the correct support to avoid the seal failure leading to internal condensation between the glass panes..

How To Fit Window Frames Correctly With Packers.

The jobs of the glazing packer can best be evaluated when installed.

The following points should be taken into account so that the edge of

the glass and composite edge of the insulating glass are not

overstressed during glazing-in, thus avoiding any glass breakage:

- The packers make sure that the glass edges never make contact with the frame and therefore prevent damage.

- They keep the frame and sealed unit in the right position with no distortion or buckling of either.

- The packers to evenly distribute the weight of the glass unit into the frame.

- The frames must be stable and the correct dimensions so that the weight of the glazing units is supported without issues.

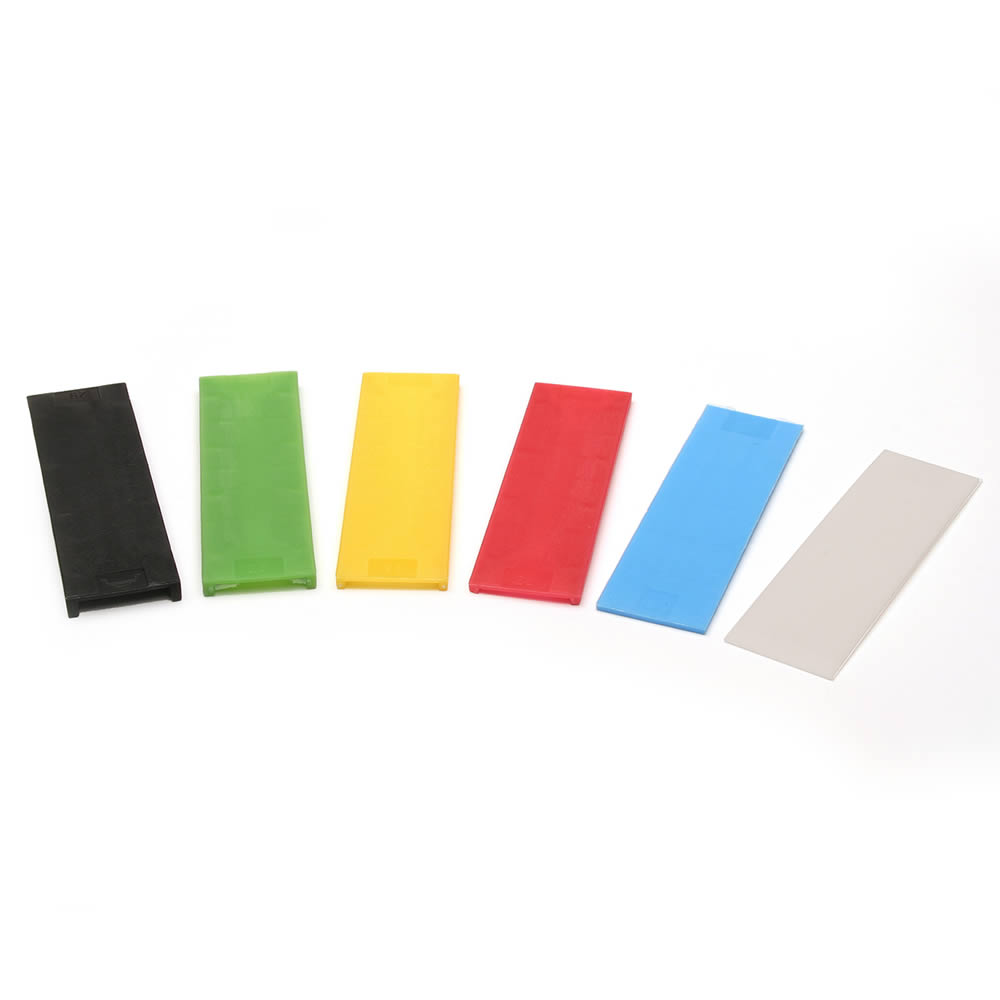

The glass unit is positioned on the lower packers and carefully angled into the frame. Place a packer on the upper end of the closing side, diagonal to the corner support. Make sure the packers is sitting tight so it doesn’t change its position later on. Aligned the packer straight

and parallel to the edge of the glass so it supports the full thickness of the glazing unit. The packer should be about 2 mm wider than the glazing unit that it is supporting.

- Place the plastic packers around 100mm in from each corner. This distance in is typically one packers length of 100mm

- Carefully place the double glazed unit into the frame making sure of the correct positioning on the glass packers.

- Carefully place the double glazed unit into the frame making sure of the correct positioning on the glass packers.

From years of experience it has been shown that the optimal packer length should be 100 mm to help reduce the load points and therefore reduce the risk of breakage of the insulating glass unit.

It is important that glass packers are used to support the double glazed units to prevent them from standing in any water that may collect, at the bottom, in the frame. If sat in water it can cause seal of the double glazing to fail and will probably invalidate your guarantee if packers have been proved not to be used. Remembering that packers must not cover the drainage holes in the frame as this could cause similar standing water issues. The whole of the double glazed unit must be supported by the packer (packers being 2mm’s wider than the unit). Known as toe & heeling the objective is to transfer the weight of the glass onto the frame. Correct use of this technique will give trouble free fitting, once the vents have been set correctly. The vent should be flexed upwards if necessary to allow the insertion of the top packers.

Additional packers are generally required for window sizes over 1500mm.

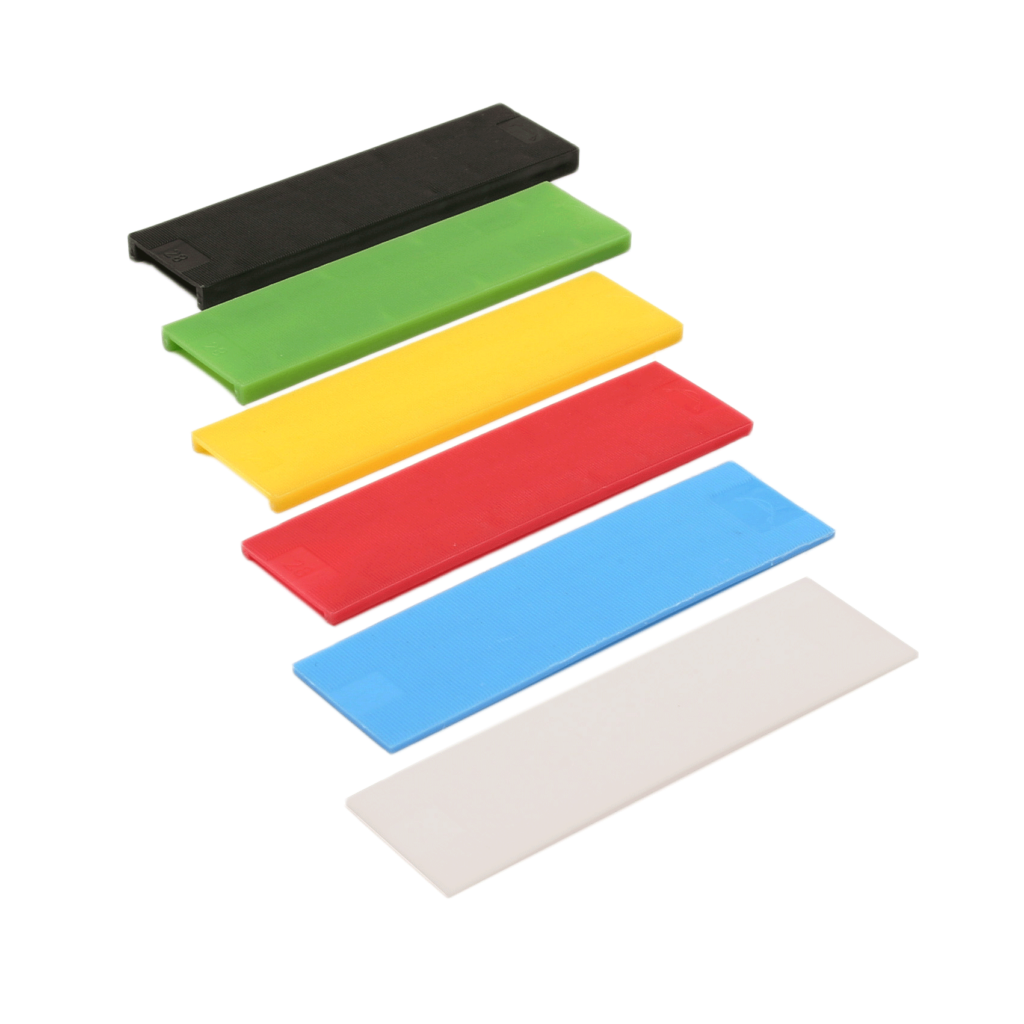

When would I use a Bridging packer instead of a Glazing packer?

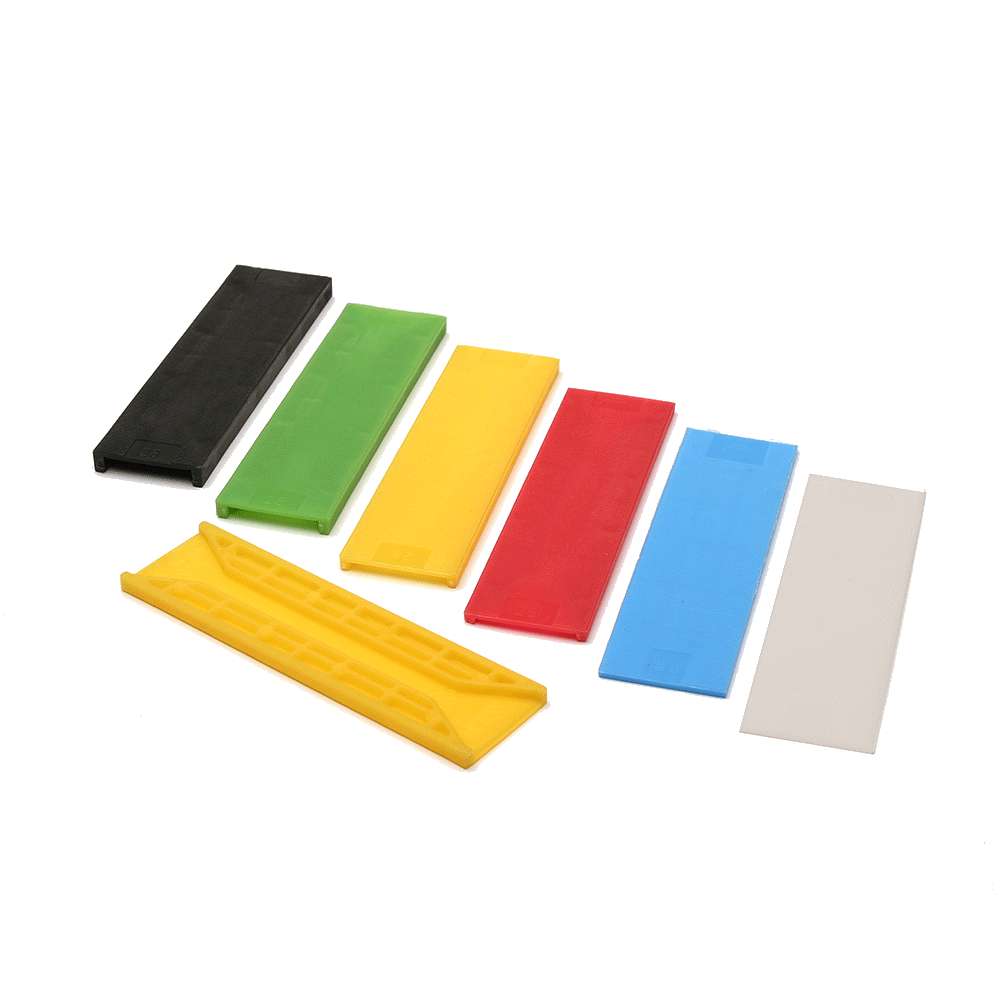

Bridging packers are designed with a drainage channel in the middle, running down the length, to help maintain drainage and ventilation in the window frame. The bridging packers will offer the same support that a glazing packer does whilst maintaining an escape and ventilation routes around the insulated glazed units for any water.

In Conclusion

The glazing packers should:

- Transfer the weight of the glazing unit to the frame construction

- Keep the distance between the edge of the glass unit and base of the frame.

- Prevent the excessive sagging of frame profiles when mechanical loads are introduced

The packers should be capable of:

- High carrying capacity through reinforced web system

- Compatible with compound edge seals for insulating glass

- Non-ageing

- Temperature-resistant

In addition to window units packers are also used for doors, bi fold and patio door sets.

Our glazing packers are available in a variety sizes & thickness’s at great low trade prices, including our very popular mixed boxes allowing you to minimise the amount you are stocking on the van

To buy our great packers click on either:

Why It’s Important To Use Genuine Polytops

What Are Polytops? Original Polytops, also known as Polytop Pins & Polytop Nails, were first innovated by SEAC over 40 years ago. They are the

Features & Benefits of Concrete Screws

Whether you are securing windows, doors, or fastening materials, the choice of fixings and screws can significantly impact both the efficiency and longevity of a

Breathable Roofing Membrane For Outbuildings

The benefits and uses of breathable roofing membrane Breathable roofing membrane is a material that contains many practical properties, and its popularity has exploded in

Why POLYTOPS Nails and Pins are the best fasteners for Fascia and Soffits

If you are planning to spend several £1000’s to fit new fascia’s and soffits on your house, you want them to look good, which is

How are glazing packers used?

Glazing packers are an important element for professional installation of window units. By levelling up the units to the correct heights, packers help ensure both

Do I need Wall Plugs with Fix Direct screw products?

It all depends on the application and what screw fastener you are using. We have a range screw fasteners and most don’t need a wall